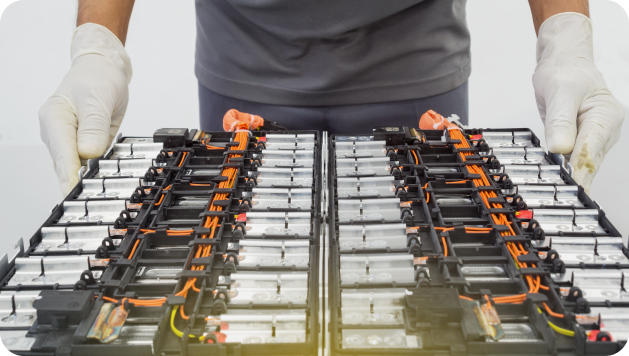

PACKS

CELLS

PACKS

We see value where others see waste

Battery metals from end-of-life batteries do not degrade when recycled, providing valuable

sources that can be reused indefinitely. At Exigo,

we recycle and re-manufacture from all different

kinds of batteries through our in-house designed

technology.

Undertaking recycling of different battery chemistries

Recovering battery-grade material by processing different chemical compositions through unique processes

LFP

Lithium Iron Phosphate

NMC

Lithium Nickel

Manganese Cobalt Oxide

LCO

Lithium Cobalt Oxide

LTO

Lithium Titanium Oxide

ZMO

Zinc Manganese oxide

NiMH

Nickel Metal Hydride

Undertaking recycling of different battery chemistries

Recovering battery-grade material by processing different chemical compositions through unique processes

LFP

Lithium Iron Phosphate

NMC

Lithium Nickel

Manganese Cobalt Oxide

LCO

Lithium Cobalt Oxide

LTO

Lithium Titanium Oxide

ZMO

Zinc Manganese oxide

NiMH

Nickel Metal Hydride

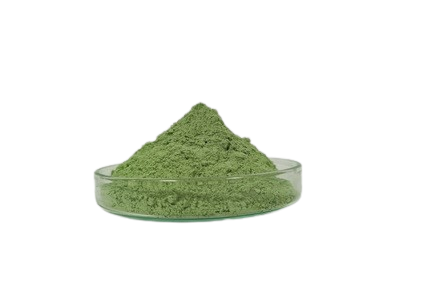

Recovering valuable and strategic materials

Responsible processing of batteries to recover materials with the highest purity standards

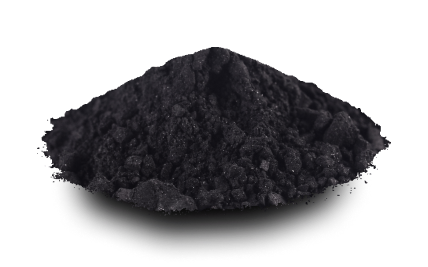

Graphite

12 g/mol

>98%

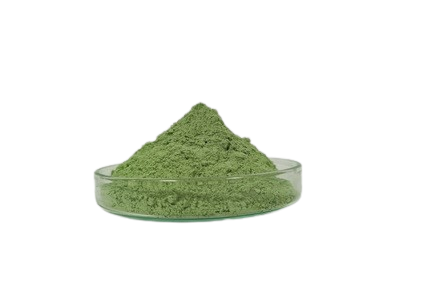

Mixed Hydroxide Precipitate

Ni>50%

95%

Li2CO3

73.891 g/mol

>95%

NiSO₄

154.75 g/mol

>95%

MnO2

86.94 g/mol

>95%

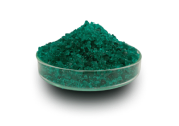

CoSO4

154.996 g/mol

>95%

Graphene

12.01 g/mol

>98%

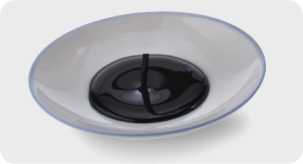

Electrolyte

73.891 g/mol

xx%

Graphite

12 g/mol

>98%

Battery Grade Graphite

Mixed Hydroxide Precipitate

Ni > 50%

>95%

Mixed Hydroxide Precipitate

Li2CO3

73.891 g/mol

>95%

Lithium Carbonate

NiSO₄

154.75 g/mol

>95%

Nickel Sulphate

MnO2

86.94 g/mol

>95%

Manganese Oxide

CoSO4

154.996 g/mol

>95%

Cobalt Sulphate

Graphene

12.01 g/mol

>98%

Graphene

Electrolyte

73.891 g/mol

>98%

Electrolyte

Battery to Battery - Closed loop recycling enabling procurement of battery grade materials

Closed loop recycling enabling procurement of battery-grade cathode and anode materials

Cathode and Anode Materials

The salts we produce and recover are all eligible to be tested for cathode-active material. Anode-grade graphite is a by-product of our hydrometallurgical process with minor downstream processing. This can be tested for anode-active material and C-rates in battery applications.

Appearance

Ash content

Battery manufacturing

BET surface area

Cell manufacturing

Chemical element

Chemical name

Conductivity

Country of origin

Cycle capacity retention @50%

Rate capacity retention

SEM images

Specific discharge capacity

Tap density

Appearance

Ash content

Battery manufacturing

BET surface area

Cell Manufacturing

Chemical element

Chemical name

Conductivity

Country of origin

Cycle capacity retention @50%

Moisture

Molecular weight

Particle size- D10. D50, D90

Product name

Purity

Rate capacity retention

SEM images

Specific discharge capacity

Tap density

Slurry Making

Our technology is built to tailor the slurry parameters (viscosity, solid/ liquid ratio, solvents/ aqueous/organic) suitable for direct cathode/anode applications.

Slurry Density (g/cm3)

Slurry Viscosity (Pa.s)

Slurry Solid Weight Percent (%)

Slurry Surface Tension (mN/m)

Slurry Density (g/cm3)

Slurry Viscosity (Pa.s)

Slurry Solid Weight Percent (%)

Slurry Surface Tension (mN/m)

Solving the raw material needs to empower the growth of various industries

Solving the raw material needs to empower the growth of various industries

EV

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo..

Phone

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Glassware

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

EV 1

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo..

Phone 1

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Glassware 1

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Supplementing the raw material needs of various industries

Aerospace and space industry

Air purification

Automotive parts manufacturing

Cell manufacturing

Agriculture

Alloy manufacturing

Battery manufacturing

Construction

Ceramic manufacturing

Foundry

Gas turbine manufacturing

Inks and pigment manufacturing

Continuous casting

Food processing

Glass industry

Incineration system manufacturing

Lubricate manufacturing

Medical devices (MRI machine)

Pharmaceutical (Vitamin B12)

Rechargeable batteries

Machinery manufacturing

Petroleum and gas industry

Plating

Steel manufacturing

Toy industry

Textile

Aerospace and space industry

Agriculture

Air purification

Alloy manufacturing

Automotive parts manufacturing

Battery manufacturing

Cell manufacturing

Construction

Ceramic manufacturing

Continuous casting

Foundry

Food processing

Gas turbine manufacturing

Glass industry

Inks and pigment manufacturing

Incineration system manufacturing

Lubricate manufacturing

Machinery manufacturing

Medical devices (MRI machine)

Petroleum and gas industry

Pharmaceutical (Vitamin B12)

Plating

Rechargeable batteries

Steel manufacturing

Toy industry

Textile